Auto Chemical Dosing System

Price 100000 INR/ Unit

Auto Chemical Dosing System Specification

- Automation Grade

- Automatic

- Measurement

- Precise Volumetric Dosing

- Efficiency

- Over 95%

- Temperature

- 10-60C Celsius (oC)

- Instruments Type

- Online Dosing Instrumentation

- Usage & Applications

- Industrial water & wastewater treatment, chemical processing

- Display Type

- Digital Control Panel

- Power Source

- Electric

- Orientation

- Vertical

- Sensor Type

- Level & Flow Sensors

- Product Type

- Chemical Dosing System

- Material

- Stainless Steel

- Cooling System

- Water Cooling

- Reactor Thickness

- 4-8 Millimeter (mm)

- Processing Time

- Up to 30 minutes per batch Minutes

- Capacity

- 50-500 L/hr Ltr/hr

- Voltage

- 110-220 Volt (v)

- Weight

- 45-120 kg Kilograms (kg)

- Dimension (L*W*H)

- 1200x800x1500 mm Millimeter (mm)

- Surface

- Polished Stainless Steel

- Dosing Pumps

- Diaphragm Type, Adjustable

- IP Rating

- IP54 or above

- Operation

- Continuous & Batch

- Mounting Type

- Skid Mounted

- Control System

- Microprocessor Based

- Chemical Compatibility

- Acids, Alkalis, Coagulants, Disinfectants

- Tank Material

- SS 304/316

- Input Connection

- 1 Inch Female Thread

- Safety Features

- Overload & Dry Run Protection

- Supply Frequency

- 50/60 Hz

Auto Chemical Dosing System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- Karnataka, Kerala, Arunachal Pradesh, Tamil Nadu, Telangana

About Auto Chemical Dosing System

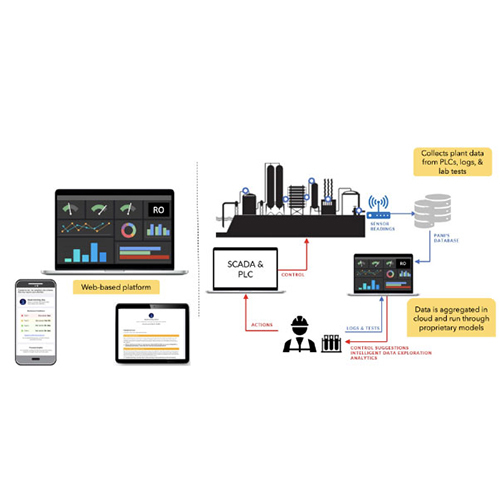

Automation Dosing Systems, Online Analyzers

- Offline Water Parameter Test Kits & Meters

- Online Water Quality Parameter Monitoring & Cintrol

- Remote Water Quality Monitoring ( Web Based)

We help you monitor all the water parameters through online & offline test methods at your premise or remotely from your home.

Automated Chemical Dosing System For Swimming Pools, Boilers, Cooling Towers & Chiller, STP & ETP

We offer one of the most powerful family of online process controllers in the water treatment industry. TCPL couples a powerful multi I/O platform with our analytical sensors and extensive communications technologies. The result is the ability to remotely monitor and control your process from any computer, anywhere in the world, with just a standard web browser.

Simple, intuitive programming makes it easy to configure your controller to control multiple cooling towers, boilers, closed loops, or virtually any water treatment process.

Wide range of direct sensor measurements :

- Conductivity

- pH/ORP

- Free Chlorine/Bromine

- Electrodeless Conductivity

- Chlorine Dioxide

- Turbidity

- COD/BOD TOC

All standard water treatment control methods are included in every of our Controllers :

- On/Off and Time Proportional Control

- Inhibitor feed

- Intermittent boiler sampling with flashing detection

- Biocide timers

- ORP spike feed of chlorine

- Volume based cycles control

Instant alarm notification via email or text message System status reports and datalog files can be sent automatically Available with Modbus TCP/IP protocol

Smart Dosing System

- Tank MOC : FRP for outdoor installation and LDPE for indoor installation

- Easy to install

- Highly durable

- Accurate, Precise & Reliable dosing

- Optional features: Agitator with various MOC , level switch with low level TRIP interlock

Advanced Automation & Precise Control

The system integrates a microprocessor-based controller and online dosing instrumentation, providing extremely accurate volumetric dosing for a wide range of chemicals, including acids, alkalis, coagulants, and disinfectants. The digital control panel and level & flow sensors streamline monitoring and adjustments, minimizing manual intervention and ensuring process consistency.

Robust & Durable Construction

Built on a reliable skid-mounted frame with reactor thickness of 4-8 mm and polished stainless steel surface, the dosing system withstands challenging environments and aggressive chemicals. Its components, including SS 304/316 tanks, water-cooled mechanisms, and IP54 or higher-rated enclosure, ensure long service life and operational safety.

Safety & Efficiency Ensured

Safety features such as overload and dry run protection, along with efficient water cooling, safeguard both operators and the equipment. The automatic, electric-powered system operates at low noise levels and maintains over 95% dosing efficiency for continuous or batch processes.

FAQs of Auto chemical dosing system:

Q: How does the auto chemical dosing system ensure accurate dosing?

A: The system utilizes a microprocessor-based controller and precise, adjustable diaphragm dosing pumps, coupled with level and flow sensors, to guarantee accurate volumetric dosing. The digital control panel allows real-time monitoring and adjustments, optimizing chemical feed rates for maximum process efficiency.Q: What types of chemicals can be handled by this dosing system?

A: This dosing system is compatible with a wide range of chemicals, including acids, alkalis, coagulants, and disinfectants, making it suitable for various industrial applications such as water and wastewater treatment and chemical processing.Q: When should the auto chemical dosing system be used?

A: It is ideal for use in processes requiring continuous or batch-wise precise chemical dosing, especially where safety, accuracy, and efficiency are critical, such as industrial water treatment and chemical manufacturing operations.Q: Where is this system best installed and utilized?

A: The skid-mounted design facilitates flexible installation in industrial plants, particularly in water and wastewater treatment facilities, chemical processing units, and any site requiring automated chemical dosing in a demanding environment.Q: What is the operation process for this chemical dosing system?

A: The operator sets process parameters using the digital control panel. The system then automatically withdraws chemicals from the stainless steel tank and uses adjustable diaphragm pumps to deliver precise dosages. Sensors continually monitor levels and flows, and safety features protect against operational faults.Q: How does the system benefit industrial operations?

A: By automating precise chemical dosing, the system reduces manual intervention, enhances operational safety, ensures chemical compatibility, and achieves over 95% efficiency. This leads to improved process consistency, reduced chemical waste, and lower operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIGITIZATION Category

Online Water Parameter Monitoring

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Online Water parameter monitoring

Material : Stainless Steel

Cooling System : Water Cooling

Voltage : 110220 Volt (v)

Energy Monitoring System

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Energy Monitoring System

Material : Stainless Steel

Cooling System : Water Cooling

Voltage : 110220 Volt (v)

Engineered Adsorption Systems

Price 70000 INR / Unit

Minimum Order Quantity : 1 Piece

Product Type : Engineered Adsorption Systems

Material : Mild Steel

Cooling System : Water Cooling

Automation Dosing Systems Online Analyzers

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Automation Dosing Systems Online Analyzers

Material : Mild Steel

Cooling System : Water Cooling

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese